How to select a wood shredder machine based on material size?

Understanding Material Size and Its Impact on Wood Shredder Performance

The Role of Maximum Branch Diameter Handling in Equipment Choice

When it comes to picking out a wood shredder, the first thing anyone needs to figure out is what kind of branch sizes they deal with most often. Hardwoods at around 3 inches thick actually need about 30 percent extra power compared to similar sized softwoods. That means getting the right machine matters a lot if someone wants their equipment to last through regular use instead of breaking down too soon. Going bigger than needed just because there might be occasional big branches ends up costing more in fuel and repairs over time. According to industry standards from groups like ASABE, most operators find good results when they choose machines that can handle about 85% of their usual largest materials. This approach tends to work best for keeping things running smoothly without wasting resources.

Matching Wood Shredder Machine Capacity to Yard Waste Volume and Material Type

The difference between residential units that handle about half a cubic yard per hour of pine needles and commercial models capable of processing three times that amount in mixed oak is pretty substantial. When it comes to hardwoods such as hickory, they generally require around 15 to 20 percent more horsepower compared to softwoods when running at similar speeds, something Taylor & Francis noted in their recent biomass processing study from 2023. Practical experience shows that when dealing with all sorts of mixed debris, it's wise for operators to go for equipment with roughly 25 to 35 percent extra capacity. This buffer helps keep things running smoothly without pushing the machine beyond its limits during those unpredictable days when the material composition changes unexpectedly.

How Material Size Influences Chipping Efficiency and Machine Strain

Branches just 1 inch over a shredder's rated capacity reduce chipping efficiency by 30–40% and raise bearing temperatures by 60°F, accelerating component failure. Properly sized machines operate at less than 85% engine load continuously, while undersized units experience power spikes exceeding 110% of rated capacity during peak demands.

Common Challenges When Processing Oversized or Mixed-Size Debris

Landscapers face 73% higher blade replacement costs when processing ungraded debris compared to sorted materials. Mixed loads containing both 9-inch logs and 0.5-inch twigs cause 42% more feed system jams due to inconsistent flow. Pre-shredding into three size categories (<2", 2–4", 4+") reduces unplanned downtime by 60% in field tests.

Wood Shredder Capacity and Branch Size Handling: Matching Machine to Input

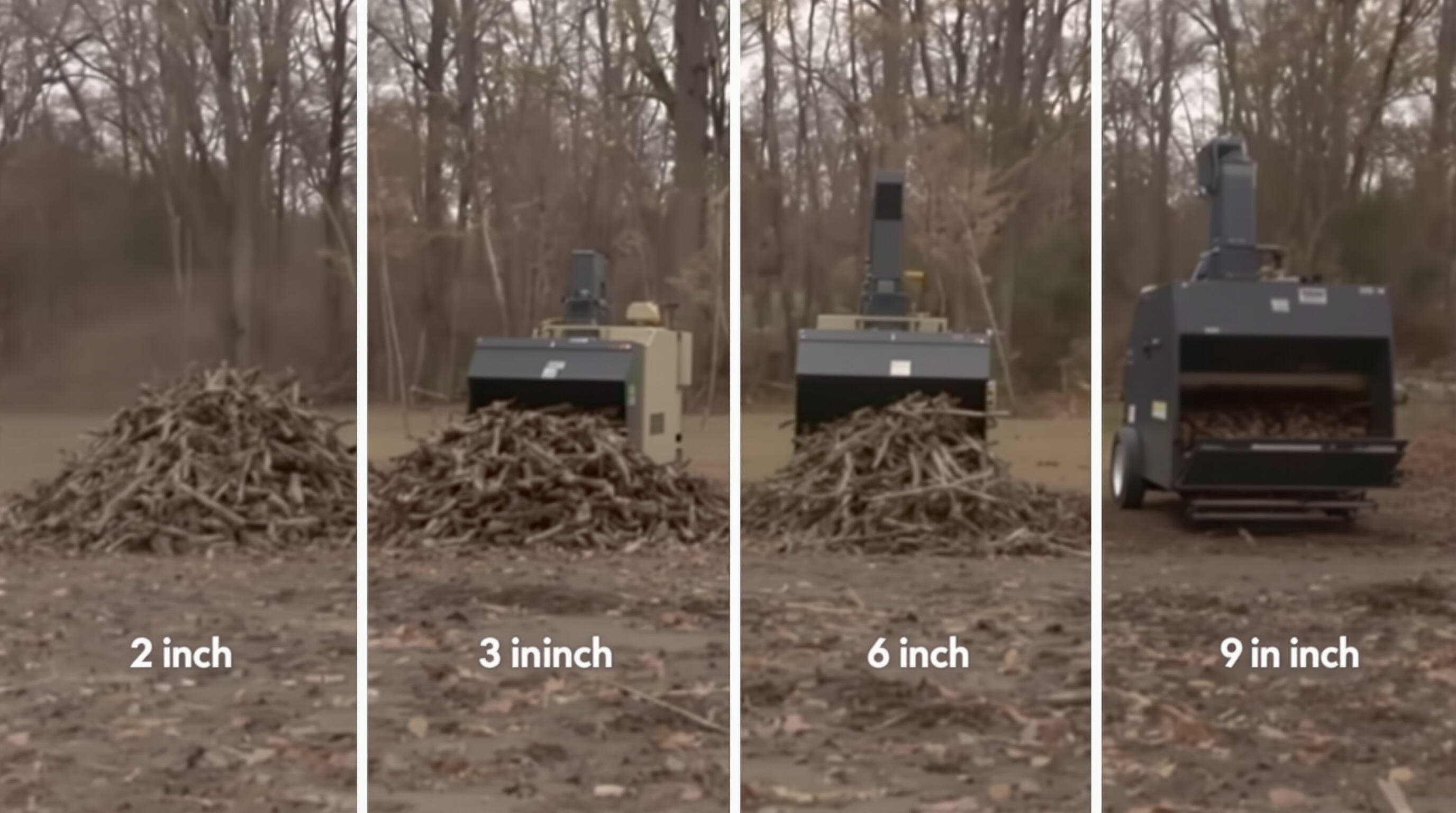

Evaluating Chipping Capacity for Branches up to 2 Inches, 3 Inches, or Over 9 Inches

The amount of wood a shredder can process really comes down to what size branches it handles well. Most home units work fine with 2 to 3 inch diameter branches and will churn out around 2 to 4 cubic yards of mulch each hour. But when we're talking about bigger stuff, like those commercial machines that tackle 9 inch logs, they need serious power behind them – somewhere between 50 and even over 100 horsepower just to keep running without burning out. Try feeding in material that's too big for the machine and things start going wrong fast. Efficiency drops by roughly 40 to 60 percent, and the hammer parts get worn down much quicker than normal. That's why manufacturers sort their equipment into different categories based on these size limits. Makes life easier for folks who deal with regular volumes of yard waste day after day.

Correlating Wood Shredder Machine Size With Average Branch Diameter for Optimal Throughput

Optimal throughput requires aligning shredder size with median branch diameter. A machine processing 3-inch branches at 2 tons/hour drops to 0.8 tons/hour with 5-inch limbs, increasing fuel consumption by 35%. This mismatch also leads to 27% more annual blade replacements compared to properly matched equipment.

Data Comparison: Processing Times for Different Diameter Branches

Research from ASABE standards highlights the impact of branch size on efficiency:

| Branch Diameter | Processing Rate (tons/hour) | Ideal Shredder Power (HP) |

|---|---|---|

| 2 inches | 4.2 | 30–40 |

| 3 inches | 3.1 | 45–60 |

| 6 inches | 1.8 | 75–95 |

| 9 inches | 0.6 | 100+ |

Doubling branch diameter can quadruple processing time, underscoring the need for careful capacity planning.

Engine Power and Feed System Design for Efficient Size-Based Processing

Machine Power and Engine Specifications (cc, Horsepower) Required for Large-Diameter Material

Engine performance is critical when shredding dense, large-diameter wood. For branches over 6 inches, engines below 25 HP or 420 cc struggle to maintain torque, increasing wear by 23%. Industrial models handling 9-inch logs typically use 35–50 HP engines with reinforced rotors to prevent stalling and ensure durability.

Gravity vs Hydraulic Infeed Systems: Performance Differences in High-Volume Scenarios

When dealing with odd shaped or large pieces of debris, hydraulic infeed systems generally work better than gravity fed ones. They cut down on how much time varies during processing by about forty percent according to some tests. Research published in Applied Sciences back in 2020 showed another benefit too - these hydraulic setups actually save around eighteen percent more energy when working with different types of hardwood because they automatically adjust the feeding rate. For smaller stuff that's all pretty much the same size, say under three inches thick, gravity systems still make sense from a cost standpoint. But anyone who has dealt with damp wood or branches with knots knows these gravity based systems tend to get stuck quite often.

Feed Mechanism Efficiency Based on Input Material Size and Consistency

The consistency of materials being processed has a big impact on how long feed systems last. Machines that deal with pieces larger than four inches most of the time tend to wear out their chains and sprockets about three times quicker compared to equipment working with smaller, more regular sized material. When dealing with mixed size inputs, having dual direction feed rollers makes all the difference in keeping things aligned properly. And for machines running continuously, adding wear resistant steel guides really helps them stand up against tough stuff like bark and wood knots that would normally cause problems.

Reduction Ratio and Output Control: Achieving Desired Mulch Fineness

How reduction ratio affects final mulch fineness and usability

Reduction ratio determines mulch quality—higher ratios yield finer chips ideal for composting. A 10:1 ratio, for instance, turns an 8-inch branch into 0.8-inch particles. Landscapers needing nutrient-rich mulch should select shredders with ratios above 8:1, as finer material decomposes 40% faster in soil applications (Purdue University 2023).

Screen sizing principles for controlling output particle size

Adjustable screens allow precise control over chip size to meet project requirements:

| Screen Mesh Size | Typical Output | Best For |

|---|---|---|

| 2" | 1.5–2.5" chips | Erosion control |

| 1.25" | 0.75–1.5" chips | Playground surfacing |

| 0.75" | <1" particles | Rapid decomposition |

Manufacturers recommend replacing screens every 500 operating hours to maintain consistent output.

Case study: Landscape company achieving consistent mulch quality using adjustable screens

A Midwest landscaping firm improved mulch consistency by 35% after implementing screen-based calibration. By using 0.5" screens with high-reduction-ratio machines for ornamental beds and 1.75" mesh for pathways, they reduced waste by 28% while meeting diverse client needs.

Wood Shredder Machine Type for Large or Frequent Jobs

Tow-Behind vs Commercial-Grade Chippers: Portability Versus Power for Large Debris

For heavy-duty tasks, portability often trades off against power. Tow-behind models offer mobility and handle branches up to 6 inches with moderate throughput (15–25 yd³/hour). Commercial-grade chippers dominate large-scale operations, featuring hydraulic feeds and engines over 100 HP capable of processing 8–10-inch hardwood without overheating.

| Feature | Tow-Behind Chipper | Commercial Chipper |

|---|---|---|

| Max Branch Capacity | 6 inches | 10 inches |

| Avg. Engine Power | 50–75 HP | 100–150 HP |

| Maintenance Costs | $250–$400 annually | $800–$1,200 annually |

Field Data: Uptime and Maintenance Costs for Processing >6-Inch Material

Commercial operators processing >6-inch material over 30 hours weekly achieved 92% uptime using turbine cutting systems. These systems, which employ high-speed rotors to minimize jams, reduced blade replacement costs by 18% compared to gravity-fed models. However, hydraulic feed mechanisms added $300–$500 annually in maintenance due to complex fluid systems.

When Volume Justifies Investment: Matching Machine to Material Size and Job Frequency

Facilities that deal with around 20 tons or more of mixed waste each week generally get the most bang for their buck using industrial strength shredders. Smaller operations facing occasional big cleanup tasks, say up to five tons per month, often find tow behind models much more budget friendly, cutting initial expenses somewhere between 40 to 60 percent without sacrificing much productivity. According to industry guidelines, most chippers start losing steam pretty quickly once they're processing branches that take up more than three quarters of what they're rated for, especially if this goes on past two hours straight. Operators who push machines beyond these limits tend to see performance drop off significantly, sometimes falling under half of normal efficiency levels.

FAQ

What factors should I consider when choosing a wood shredder?

It's crucial to consider the size of branches you'll be handling regularly, as well as the volume and type of yard waste. Matching the machine's capacity to your needs can help avoid inefficiency and increased maintenance costs.

How does branch size affect wood shredder performance?

Larger branch sizes require more power, which impacts overall efficiency and wear. Machines not suited for the size of branches being processed can experience reduced chipping efficiency and increased maintenance issues.

Why might I choose a hydraulic infeed system over a gravity-fed one?

Hydraulic systems are generally more efficient for processing irregularly shaped or larger pieces of debris, offering more consistent processing and energy savings, especially for hardwoods.